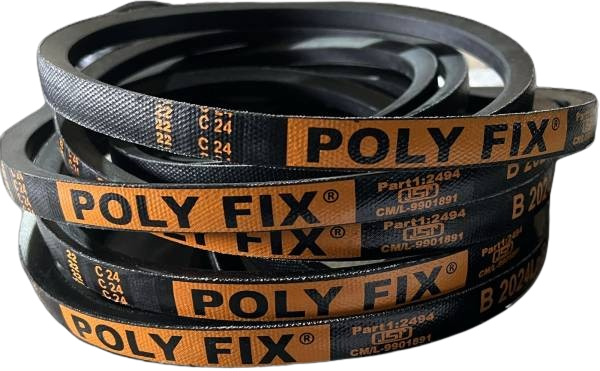

V - Belts

V belts are crucial components of machinery and gearboxes; you can find them in almost every kind of machinery, including automotive, agricultural, and industrial ones. Despite being centuries old and extremely simple, these belts are an essential component of many mechanical applications.

Available Sizes and Specifications:

A: 13.0 mm x 8.0 mm | 23” – 350” | IS 2494 & BS 3790

B: 17.0 mm x 11.0 mm | 24” – 550” | IS 2494 & BS 3790

C: 22.0 mm x 14.0 mm | 36” – 650” | IS 2494 & BS 3790

D: 32.0 mm x 19.0 mm | 70” – 650” | IS 2494 & BS 3790

E: 38.0 mm x 23.0 mm | 160” – 650” | IS 2494 & BS 3790

BB: 17.0mm x 13.9mm | 58” – 550” | IS 2494 & BS 3790

Flexible machine parts called V-Belts are used to transfer power from one component to another. Their unique trapezoidal cross sectional shape, which resembles the letter V, gave rise to their name. Typically, more than ten different kinds of rubber, thirty or more chemicals, and fabric to hold everything together are used to make these.

Advantages of V-Belts:-

FAQ - V Belts

Because of its shape, V belts offer effective power transfer even in high-torque scenarios by improving traction and preventing slippage. Their quiet operation and endurance are also well-known attributes.

When selecting the proper V belt, one must take into account many elements such as the machinery’s unique requirements, the operating environment, the power load the belt can bear, and the belt’s length and width.

It is essential to perform routine checks for wear, appropriate tension, and alignment. Regular replacements, if worn out or damaged, guarantee optimal performance and help against unplanned malfunctions.